Furniture Shredding Systems

Worn furniture is often thrown out or donated when people move, or when they invest in buying a new collection for their home or office. It also accumulates when new furniture items are damaged in shipping and must be returned. This bulky waste stream causes disposal issues for multi-tenant housing facilities, donation centers, and furniture return centers alike.

Worn furniture is often thrown out or donated when people move, or when they invest in buying a new collection for their home or office. It also accumulates when new furniture items are damaged in shipping and must be returned. This bulky waste stream causes disposal issues for multi-tenant housing facilities, donation centers, and furniture return centers alike.

The Komar Solution

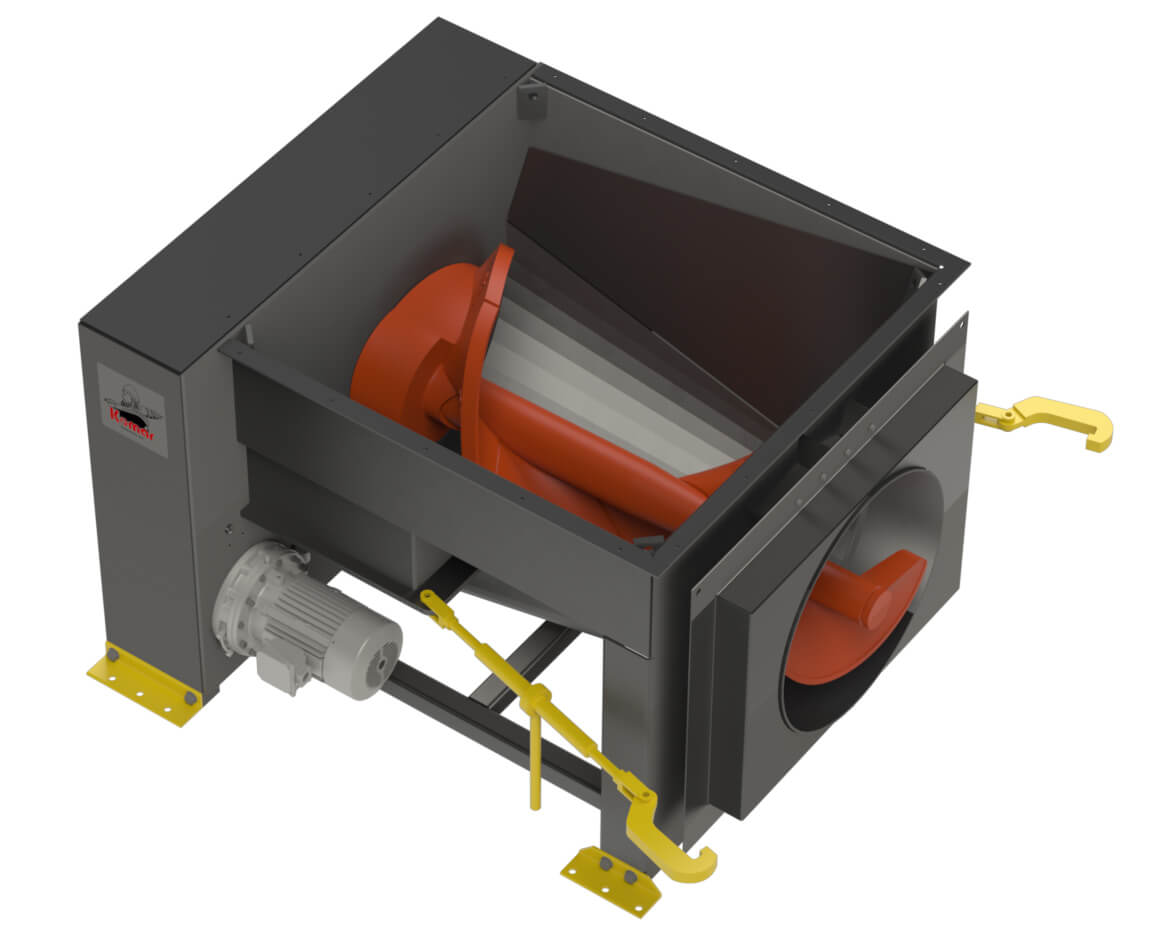

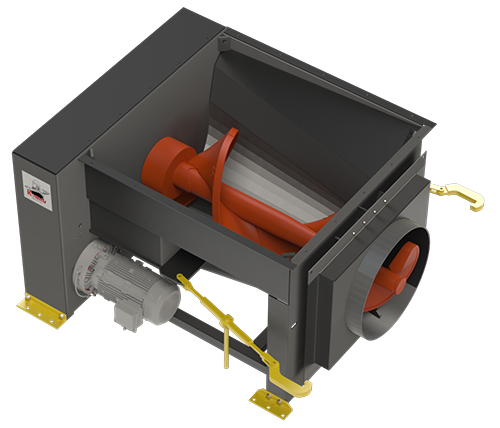

You deserve a safe, fully automated system, that shreds and compacts bulky furniture waste with ease. A solution that will quickly rid your facility and trash area of this difficult waste stream, while saving you a lot of money on hauling costs through maximum compaction. That is the job of the Komar Auger-Pak®.

What is the secret to making the best auger compactors for furniture?

Komar’s furniture processors uniquely feature auger screws that are made of solid-alloy steel shafts and cast steel flighting. This high-quality durable construction, along with a drive system that boasts a 500% shock load rating, ensures that our augers crunch through large loads with ease, year after year. In addition, our triple patented bearing support system allows us to house the largest most powerful auger screws in the industry. Our customers will tell you – if you have furniture waste – you need a Komar Auger-Pak®!

What are the biggest benefits of the Komar solution?

- Quickly Removes Stacks of Unwanted Furniture

- Furniture Shredding and Compaction in One Machine

- Eliminates Dangers of Manual Breakdown

- Substantially Reduces Transportation Costs

- Safely Handles Tramp Metal such as Nails, Bolts, and Framework

- Low Noise and Dust

Can the Auger-Pak® handle more than furniture waste?

Our auger compactors are perfect for facilities that need to tackle large volumes of mixed waste, such as donation centers and multi-tenant housing facilities. Everyday consumer items, bagged trash, and many appliances can be processed with bulk waste to consolidate all your waste handling needs into one system.

How do we select the right model and configuration for you?

The perfect furniture waste processing solution depends on many factors, such as the size, type, and volume of your material. We also consider where you would like to locate your equipment, and which feeding method best fits your operations. All models have user-friendly controls and can be integrated with material handling equipment such as electric cart dumpers. With decades of experience, the experts at Komar Industries can help select the best auger-compactor system for your needs.

Contact us for additional information

Komar Auger-Pak® Furniture Models

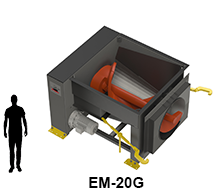

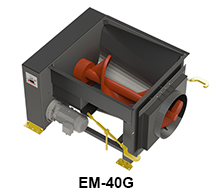

The EM-20G is the smallest Auger-Pak unit that we recommend for furniture waste. For greater compaction and heavier-duty furniture, we offer the EM-40G.

EM-20G

| EM-20G Processing Specifications | |

| Horsepower | 20 |

| Tons / Hr | 1.5 |

| Feed Type | Forklift, Tipper |

| Receiving Container | Roll-off 40 cu. yd. |

| Tons / Container | 4-8 (Depending on Material and Feed Method*) |

| EM-20G Physical Specifications | |

| Footprint (L x W x H) | 102.1″ x 83″ x 67″ |

| Chamber Size (L x W) | 70″ x 69.25″ |

| rpm | 5.97 |

| torque (ft-lbs) | 17,602 |

| Weight(lbs)** | 15,275 |

EM-40G

| EM-40G Processing Specifications | |

| Horsepower | 40 |

| Tons / Hr | 3 |

| Feed Type | Forklift, Tipper |

| Receiving Container | Roll-off 40 cu. yd. |

| Tons / Container | 6-10 (Depending on Material and Feed Method*) |

| EM-40G Physical Specifications | |

| Footprint (L x W x H) | 115.75″ x 91.75″ x 68.5″ |

| Chamber Size (L x W) | 80″ x 75.25″ |

| rpm | 7.42 |

| torque (ft-lbs) | 28,331 |

| Weight (lbs)** | 19,085 |

![]()

Site: San Jose, CA