Cardboard Processing Solutions

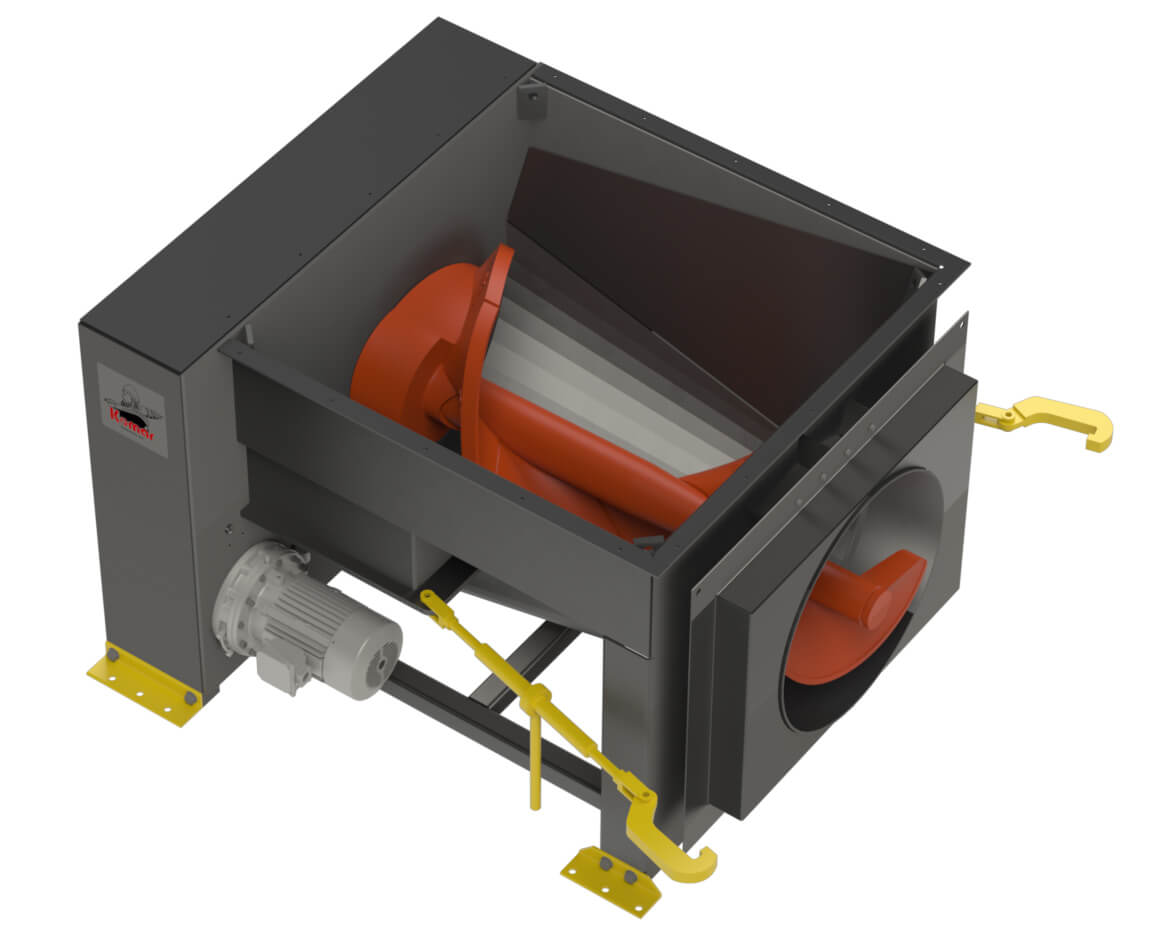

If you’re baling cardboard, you’re probably losing money. We know this goes against conventional wisdom. Most fulfillment and distribution centers believe their task is to identify which horizontal auto-tie baler will be the most efficient at producing high-density bales. What if a technology existed that produced bale-density payloads but eliminated most of the operational costs and headaches of producing bales? Welcome, the Auger Compactor.

What are the biggest benefits of the Komar solution?

- Regain Valuable Floor Space Inside of Your Facility

- Simple Design for Maximize Uptime / Minimal Maintenance

- No More Moving, Stacking, or Loading Bales

- No Expensive Baling Wire

- Low Noise and Dust

- Eliminates the Processing and Storage of Flammable Material Inside of Your Facility

- Produces Bale Density Payloads

How do we select the right model and configuration for you?

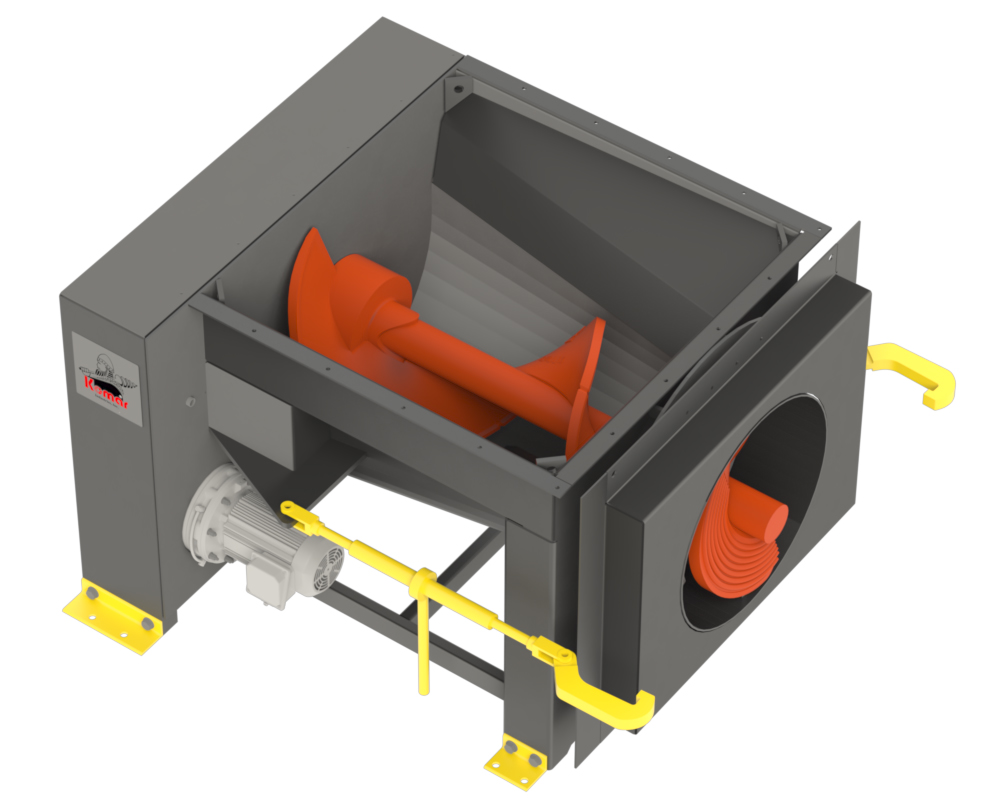

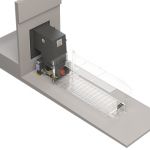

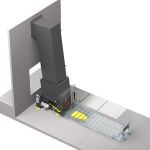

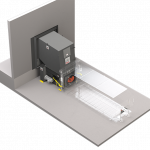

The perfect cardboard processing solution depends on many factors, such as the size, type, and volume of cardboard consumables. We also consider where you would like to locate your equipment and which feeding method best fits your operations. All models have user-friendly controls and can be integrated with material handling equipment such as electric cart dumpers and conveying systems. With decades of experience, the experts at Komar Industries can help select the best auger-compactor system for your needs.

Contact us for additional information.

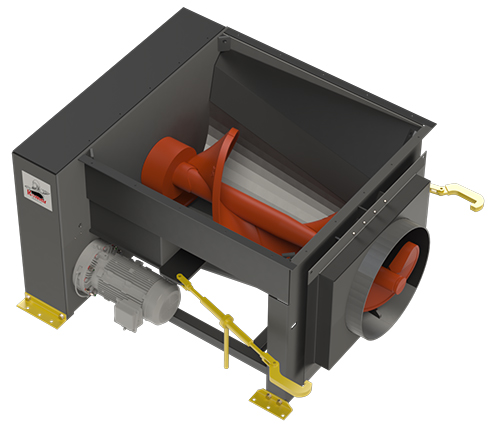

Komar Auger-Pak® Industrial Cardboard Models

We offer three cardboard units to fit your desired throughput and level of compaction.

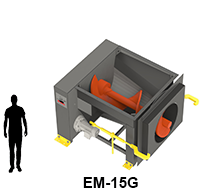

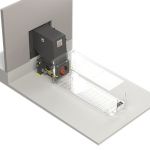

EM-15G

| EM-15G Processing Specifications | |

| Horsepower | 15 |

| Tons / Hr | 1 |

| Feed Type | Hand |

| Receiving Container | Roll-off 40 cu. yd. |

| Tons / Container | 4-8 (Depending on material and feed method*) |

| EM-15G Physical Specifications | |

| Footprint (L x W x H) | 89.6″ x 72″ x 60″ |

| Chamber Size (L x W) | 60″ x 59.25″ |

| rpm | 7.42 |

| torque (ft-lbs) | 10,624 |

| Weight (lbs)** | 10,625 |

This video gallery couldn't be loaded.

the Vimeo source for this gallery does not have any videos.

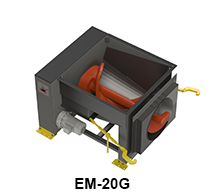

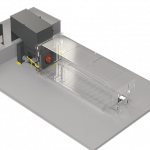

EM-20G

| EM-20G Processing Specifications | |

| Horsepower | 20 |

| Tons / Hr | 2.5 |

| Feed Type | Hand, Conveyor |

| Receiving Container | Roll-off 40 cu. yd. |

| Tons / Container | 4-8 (Depending on material and feed method*) |

| EM-20G Physical Specifications | |

| Footprint (L x W x H) | 102.1″ x 83″ x 67″ |

| Chamber Size (L x W) | 70″ x 69.4″ |

| rpm | 5.97 |

| torque (ft-lbs) | 17,602 |

| Weight (lbs)** | 11,505 |

This video gallery couldn't be loaded.

the Vimeo source for this gallery does not have any videos.

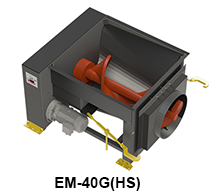

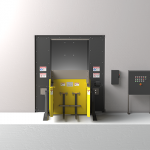

EM-40GHS

| EM-40GHS Processing Specifications | |

| Horsepower | 40 |

| Tons / Hr | 5 |

| Feed Type | Conveyor, Tipper |

| Receiving Container | Roll-off 50 cu. yd. |

| Tons / Container | 6-10 (Depending on material and feed method*) |

| EM-40GHS Physical Specifications | |

| Footprint (L x W x H) | 115.75″ x 91.75″ x 68.5″ |

| Chamber Size (L x W) | 80″ x 75.25″ |

| rpm | 14.83 |

| torque (ft-lbs) | 14,165.39 |

| Weight (lbs)** | 18,825 |